Introduction

Everyone expects and wants greater efficiency in rail transportation, but due to urban concentration and a lack of funding, it seems very unlikely that the infrastructure will be expanded. The only way to improve rail transportation performance is therefore by running more trains per hour on existing tracks. To do this, we need to overcome the challenge of braking performance limitations due to adhesion between wheels and rails.

The Wheel Slide Protection (WSP) system is the key to optimizing the use of available adhesion, thereby improving guaranteed braking performance.

In normal situations, performances are physically limited by the adhesion between the rail and the wheel, but external issues such as weather conditions and pollution can cause a reduction in the actual available adhesion. The first consequence of this is an alteration in performance, but it can also lead to costly deterioration. The main function of a WSP is to make best use of available adhesion in any external conditions, while avoiding the worse-case scenario of axle locking. It is also used to limit deterioration that could impact either rolling stock or infrastructure.

The following paper introduces Wabtec’s most recent achievements in this area, the result of continuous work both in the lab using high-performance simulation and test tools, and in the field.

The Challenges

Adverse weather conditions and pollution have a negative impact on the wheel-rail adhesion of railway transport systems, extending train braking distances. To limit this, operators require better wheel slide protection systems.

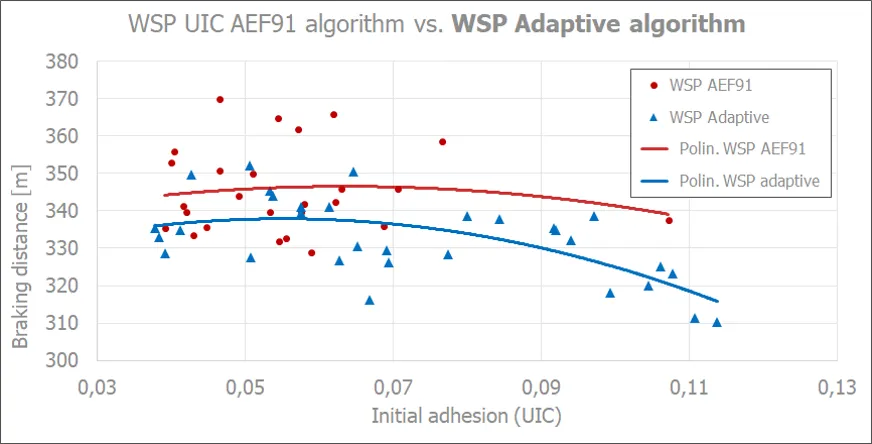

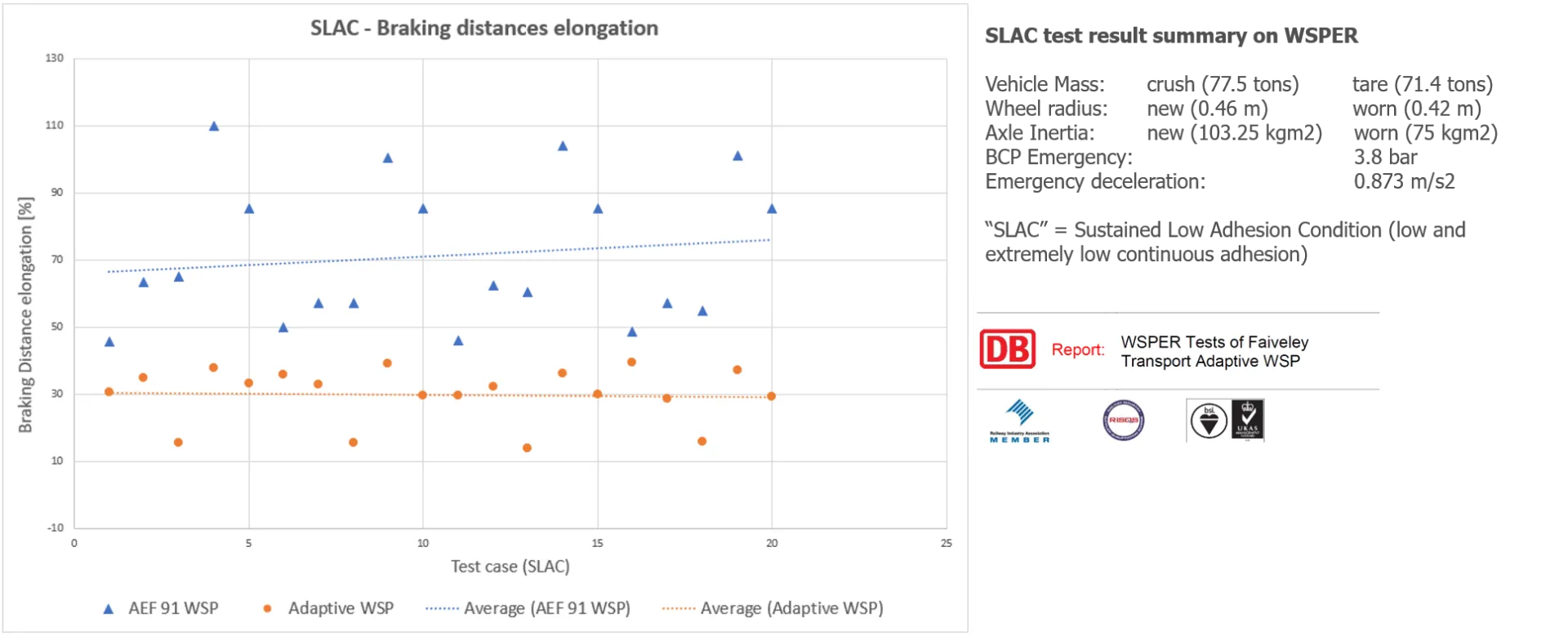

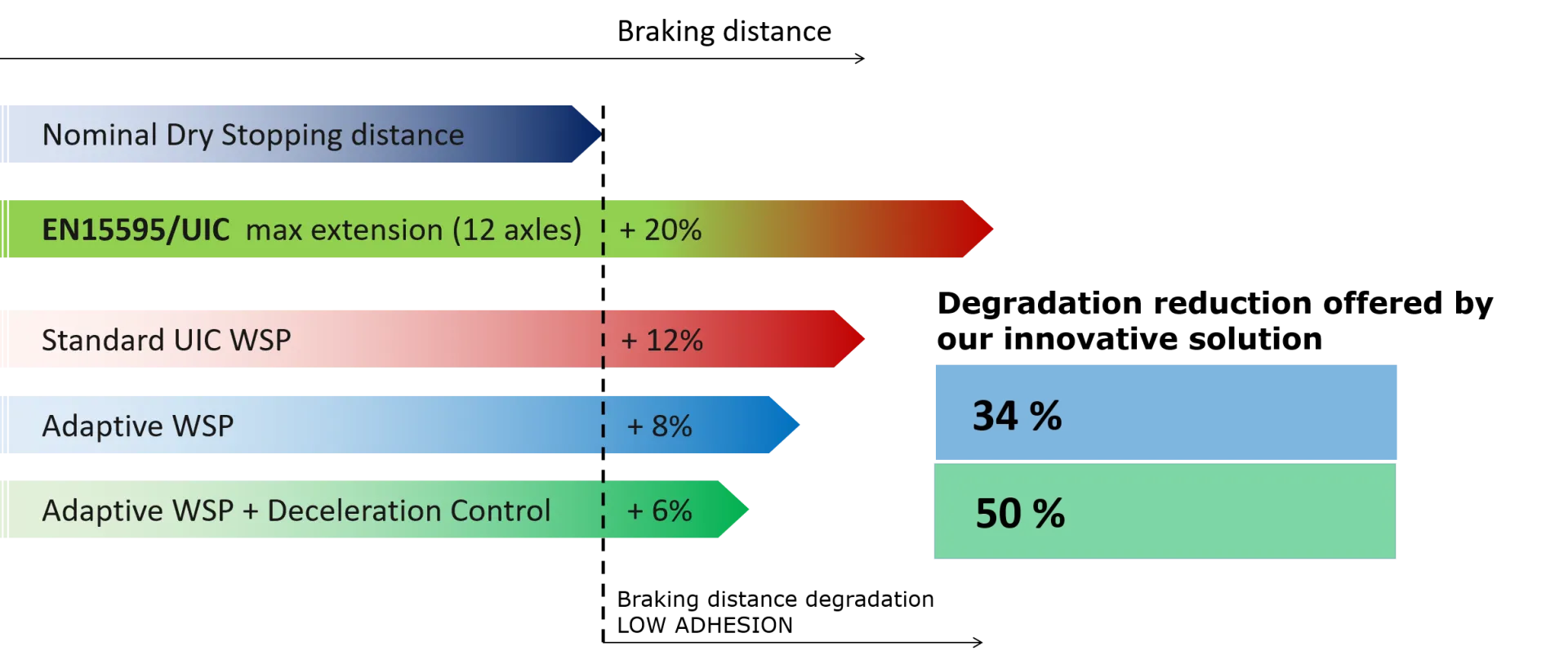

Current WSP systems are designed by considering typical degraded adhesion conditions as defined within standards, which sometimes deviate significantly from actual conditions. If adhesion is below this standard level, it can lead to the extension of braking distances by more than 50% compared to dry rail, and to the deterioration of wheels (wheel flats), obliging operators to reprofile them. This process reduces train availability and shortens wheel lifetime, generating additional maintenance costs. If adhesion is degraded even further, restrictive operational rules have to be considered, such as reducing permitted speeds or managing rail cleaning.

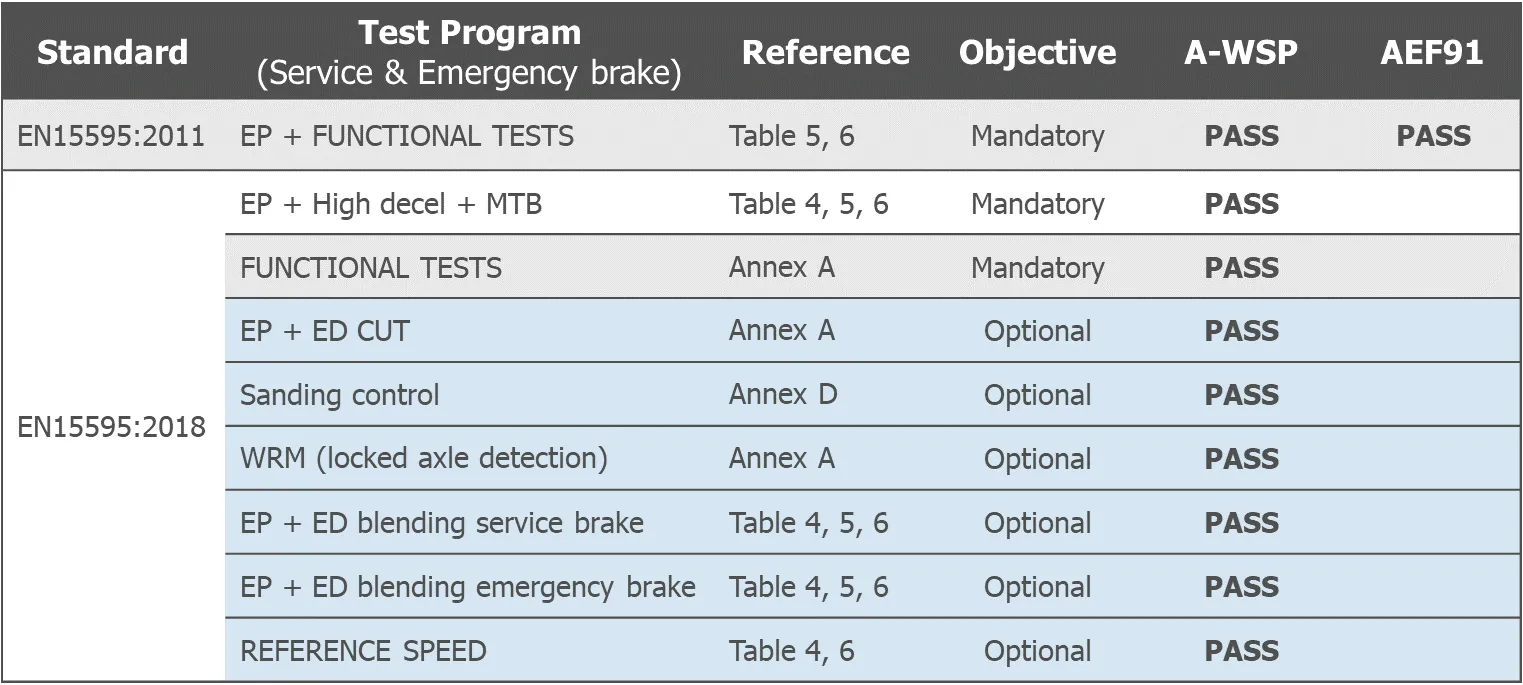

The WSP systems currently in use are qualified and tested on the basis of the adhesion models defined in the EN15595 standard (or UIC 541-05). It is a long and expensive process achieved first through test benches, then in field tests; the process takes several weeks for each new vehicle implementation.

A fixed setting cannot cover the wide range of conditions created by environmental conditions or the brake system itself:

- Actual adhesion on the rail can range from 0.01 (for example, with old leaves on the track) to 0.17; the standards consider a typical setting range for degraded adhesion conditions to be between 0.05 and 0.08.

- The improvement of adhesion along the train due to the successive run of the axles.

- Mass status (AW0 to AW3) and its dynamic change due to mass transfers.

- Friction pair performance (pad to disc or block to wheel), the friction coefficient of which changes due to speed, temperature and moisture.

In 2014, as part of the European Shift2Rail project, the railway industry - manufacturers and operators - decided to work on this problem, and Wabtec responded to the Shift2Rail challenge (PINTA1 and PINTA2 projects).

The first step was to gain a better understanding of the degradation of wheel-rail adhesion in real use conditions and environments, in particular the "cleaning" effect that can appear along the train while in service due to the successive passage of the wheels. This was achieved thanks to careful analysis of numerous test results, and extensive work on a dedicated test bench.

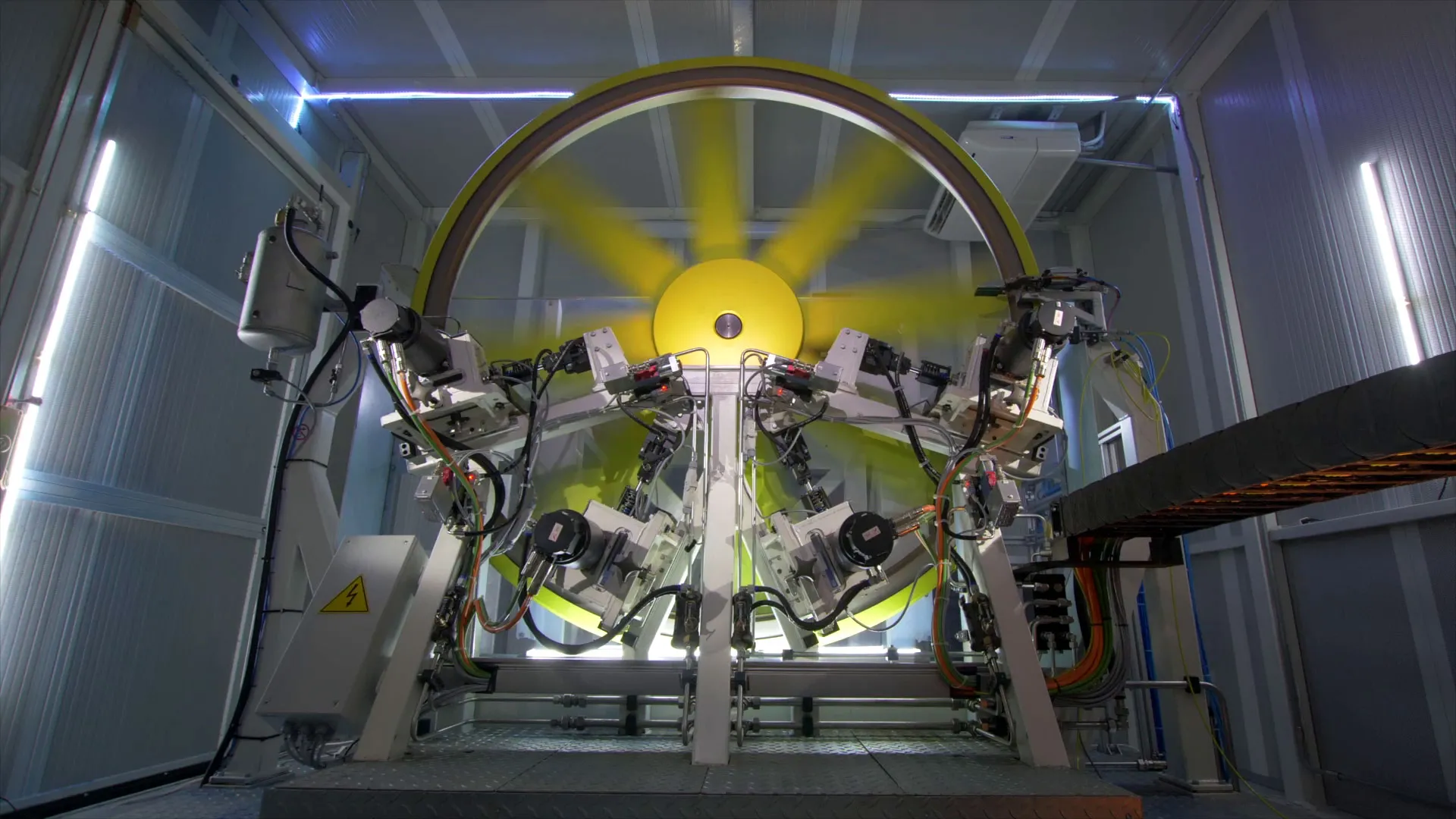

This test bench, known as Roller, was developed to simulate accurately the action of contaminants that degrade adhesion between each wheel and the rail. It is a unique tool developed by Wabtec. This test bench is a reduced-scale device that enables testers to apply braking on several axles running on the same track. Degraded adhesion is created for the track, and at each axle it is possible to modulate brake effort and assess the resulting adhesion.

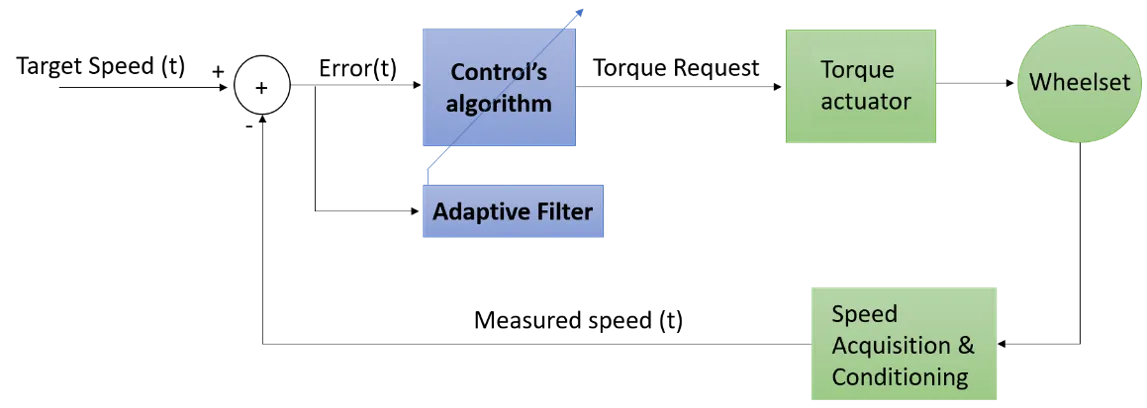

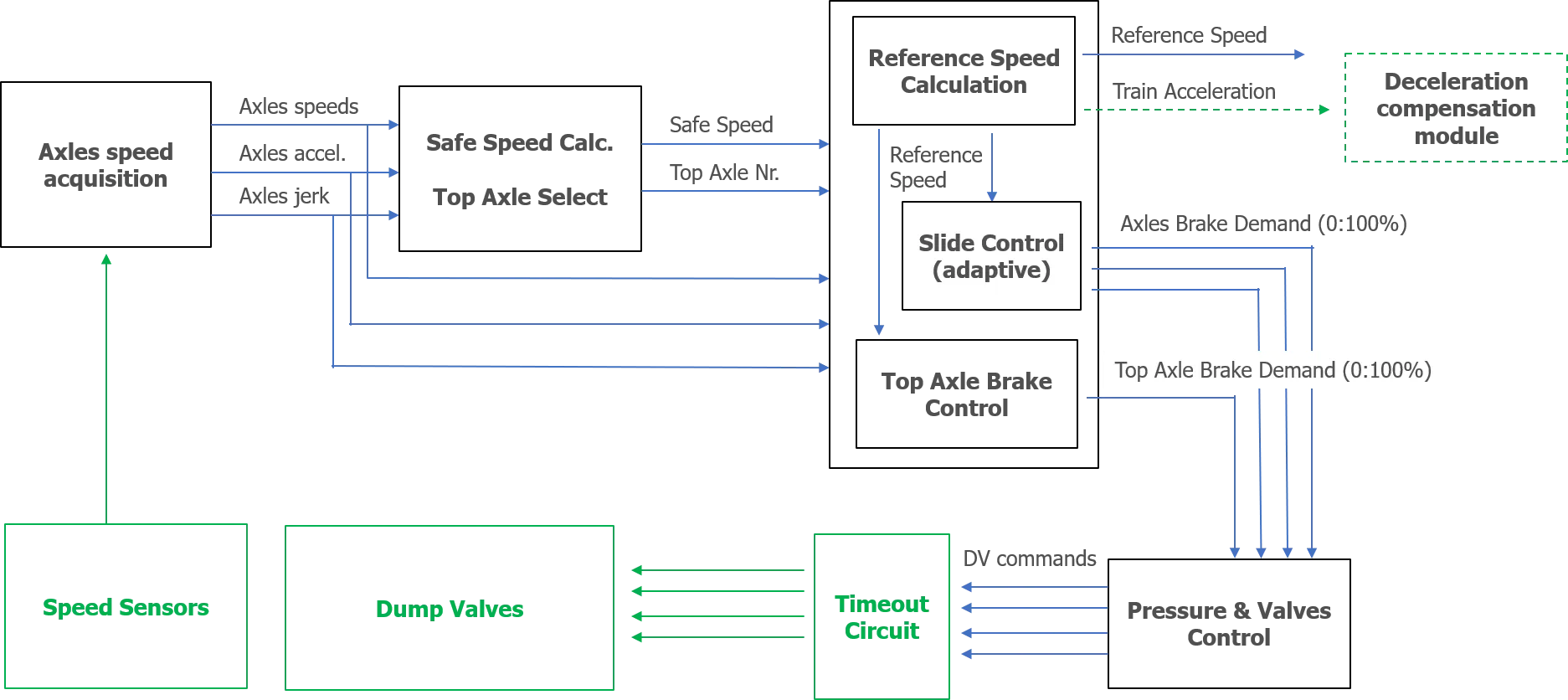

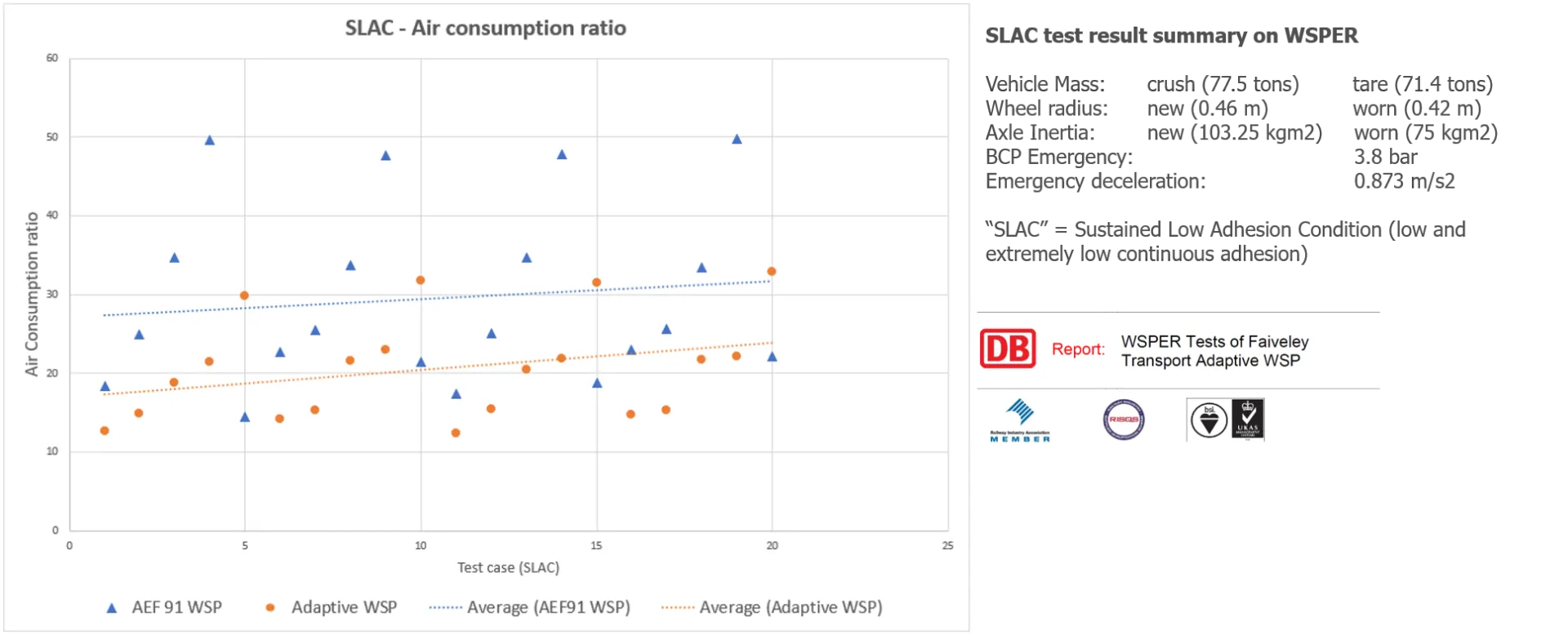

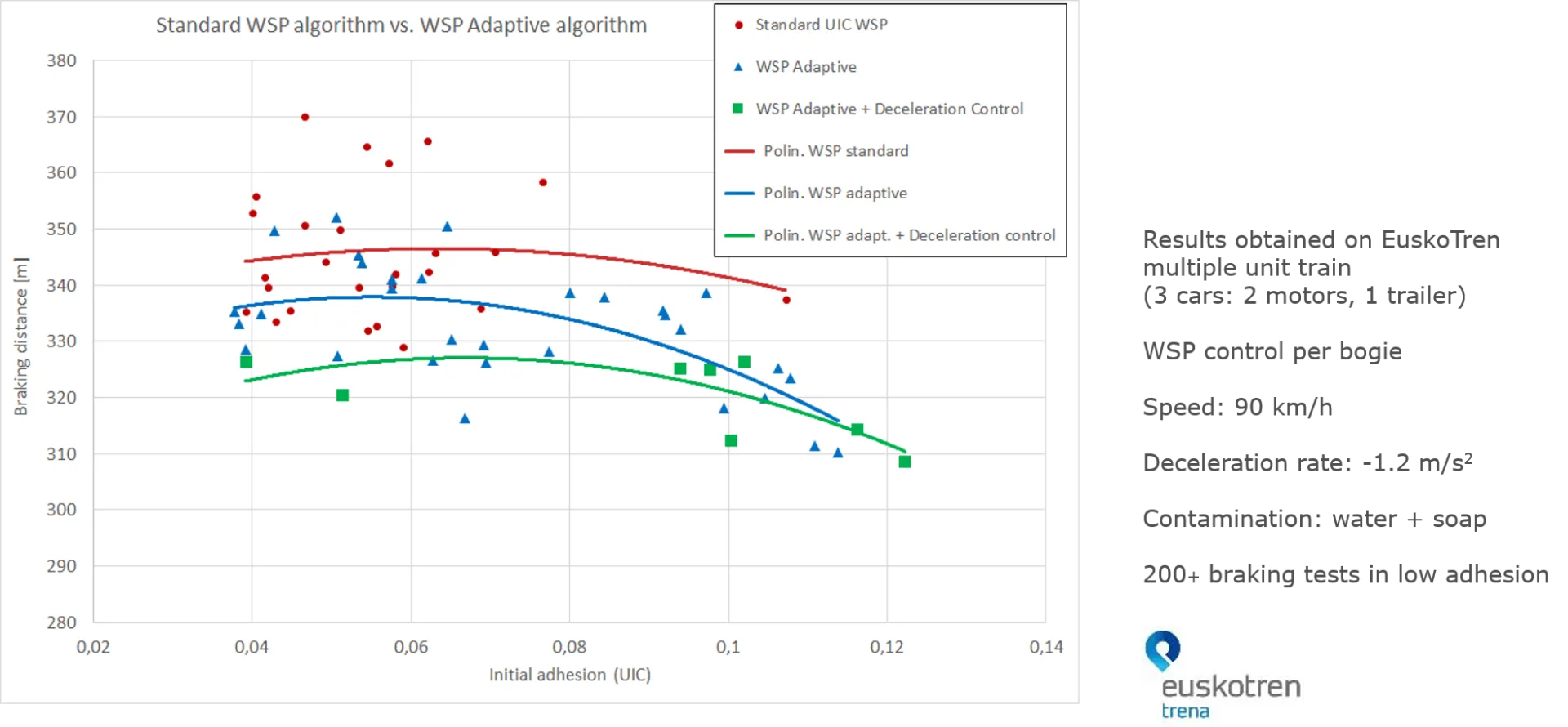

On this basis, a new Adaptive WSP system was designed and implemented. For each vehicle, digital electronic equipment, combined with a set of sensors and actuators, integrates software based on an adaptive algorithm that uses the least mean squares method (LMS). It includes dynamic self-adjustment of the WSP algorithm taking into account real adhesion conditions.

Outside of Wabtec’s lab, this new system has been tested on the WSPER test bench in the UK, on DBST’s EN15595-accredited test bench, and during field tests with an EuskoTren vehicle in Bilbao, Spain.