OPM Operational Intelligence: Increase operational efficiencies by monitoring and identifying anomalies and deviations in process material and process unit KPI.

OPM Operational Intelligence

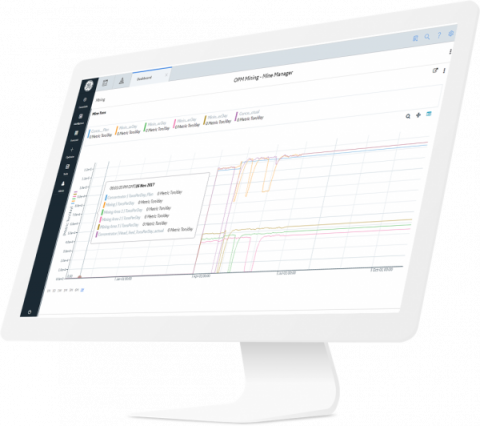

Operational Intelligence, one of the three OPM applications, helps miners increase operating efficiencies by automatically identifying and discovering causes of anomalies and deviations in business KPIs.

This is enabled by access to real-time time series data, process-performance indicators, and the latest in descriptive and diagnostic analytics. Real-time visibility to operations issues, like out of spec control loop performance, enables process engineers to quickly identify and address issues early, maximizing production and profits.

Key Benefits:

- Visualize process performance

- Automated insights

- Process Engineering Collaboration

Key Features:

- Benchmarked operational KPI’s

- Process Troubleshooter

- Case Collaboration

Operations Performance Management Forecasting & What-if Analysis

OPM Forecasting & What-if Analysis: Use scenario analysis and prescriptive Process Digital Twins of mining operations and production processes to reduce waste and increase yields.

OPM Forecast & What-if Analysis

OPM Forecasting & What-if Analysis enables process engineers to understand and proactively resolve mining process issues, thereby planning for better operating outcomes. Predictive process digital twins and analytics, coupled with what-if scenario analysis, forecast operating results to predict process issues before problems occur. By quickly addressing process anomalies, OPM Forecasting & What-if Analysis, provides the information and tools to predict and optimize product quality to increase yields.

Key Benefits:

- Operationalize process digital twins

- Forecast operational KPI performance

- Proactive decision making

Key Features:

- Process Digital Twins

- Forecast KPI Performance

- Scenario Analysis

Operations Performance Management Production and Process Optimization

OPM Production and Process Optimization: Delivers continuous process optimization either guided or completely automated, assuring product quality, reduced waste and process improvement

OPM Production and Process Optimization

OPM Production and Process Optimization enables Process Engineers to be more efficient and effective by deploying cloud to edge optimizers for either closed loop, automated edge process setpoint optimization, or open loop guided operations decision support and action recommendations to operations personnel. OPM Production and Process Optimization uses Prescriptive Analytics to enable operations personnel to ensure consistent, optimal operations performance.

Key Benefits:

- Cloud to Edge optimization

- Continuous Process optimization

- Deploy best practices across the mining fleet

Key Features:

- Guided Decision Support KPI Optimizers

- Closed Loop Automated Edge KPI Optimizers

- Operationalize and scale analytics

Proficy CSENSE

Proficy CSense: On Prem industrial analytics software that optimizes asset and process performance

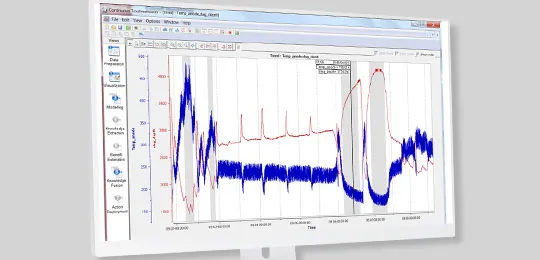

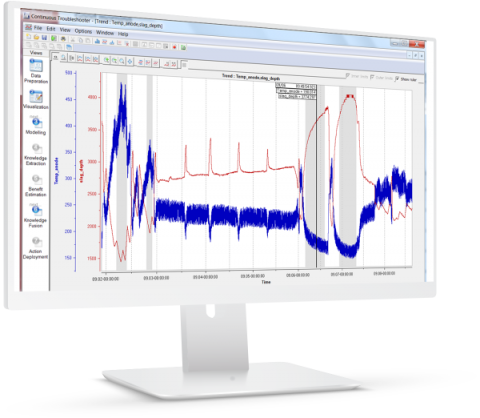

Proficy CSense

Proficy CSense uses AI and machine learning to enable process engineers to combine data across industrial data sources and rapidly identify problems, discover root causes, and automate actions to continuously improve Quality, Utilization, Productivity, and Delivery of production operations.

As proven analytics software, Proficy CSense has helped mining organizations around the world reduce costs by turning raw data into rapid business value. Engineers and data scientists can analyze, troubleshoot, predict, and optimize asset and process performance in real time.

Additionally, Proficy CSense provides the capability to mine insight from historical data and rapidly develop, test, and deploy simple calculations, predictive analytics, and optimization and control solutions to reduce variability and optimize.

Key Benefits:

- Reduce process variability

- Speed troubleshooting

- Increase engineering productivity

- Decrease downtime

- Optimize with a process twin

- Improve data integrity

Key Features:

- Mine new insight from data

- Rapidly develop analytics solutions

- Speed deployment through greater efficiency

- Enhance engineering productivity