- Locomotive

-

Freight Car

- Freight Services

-

Digital Intelligence

-

Transit

RAIL COMPONENTS

Overview Braking Systems Couplers & Draft Gears Door & Access Solutions Electrical Solutions HVAC & Comfort Systems Power Collection Power & Auxiliary Energy Solutions Sanitation Systems Suspension & Vibration ControlBUS COMPONENTS

Overview Bus Components Doors & Accessibility E-Bus Charging Electric Power Collection Passenger Information & Vehicle SecurityDIGITAL INTELLIGENCE

Radar AIC Event Recorders iSmart Display Passenger Information & Video SecuritySERVICES

Transit Services - Mining

-

Adjacent Solutions

Adjacent Solutions

RAIL INFRASTRUCTURE

Overview Track Products & Materials Signal Wayside Components Vehicle Equipment Electric Power SupplyHEAT TRANSFER & ENERGY SOLUTIONS

Overview Diesel & Gas Engine Cooling Generator, Motor & Transformer Coolers High Temperature Applications

This website no longer supports the Internet Explorer web browser.

Microsoft is retiring and will no longer support Internet Explorer. Please use another web browser to access this website.

Main Menu

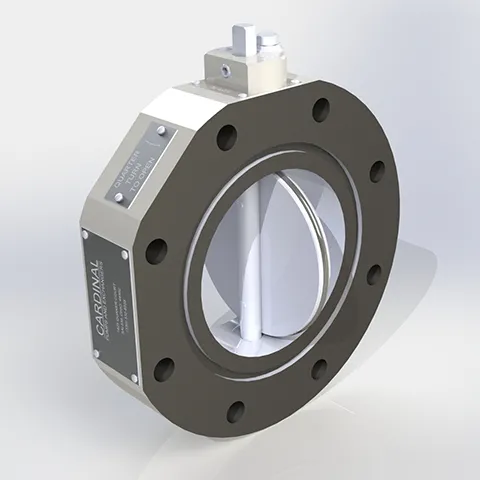

Cardinal Centrifugal & Axial Flow Pumps

Centrifugal and Axial Flow Impeller Transformer Oil Pumps

Wabtec manufactures hundreds of pump configurations used with our broad range of transformer oil coolers. They are available in both centrifugal and axial flow impeller styles and are designed to perform in extreme temperatures, with long life and low maintenance.

We also offer as an option, our TecSonics™ bearing wear monitoring system. It is an advanced predictive maintenance tool designed to monitor the integrity of the transformer oil pump bearings. See the documentation section below for the TecSonics™ App user instructions.

Features and Options:

- Heavy-duty class 30 cast iron construction for long life

- Impellers designed to permit thermo-siphon for natural convection flow

- Large thrust face sleeve bearings for long life and minimum wear

- Pump and motor unit pressure-tested to ensure integrity

- Pump continuous duty operation temperatures ranging from –40ºC (–40ºF) to 100ºC (212ºF)

- Motors available in 50 & 60 Hz frequencies

- Motor windings electrically tested to ensure electrical integrity

- Special coatings applied to protect against rust outside

- Internal surfaces of the casing can be coated to protect against rust at the customer’s request

- Special motor insulation for transformer cooling liquids other than transformer oil

- Shaft rotation sight plugs to facilitate checking shaft rotation

- Performance run-in testing and certified test curves are available

- Large thrust face bearing

Rugged Cast Iron Body

All Cardinal pumps offer rugged split casing design with heavy-duty class 30 cast iron used for the pump casting, motor enclosures, impellers and volutes to provide long life in the field.

Precision-Made Sleeve Bearings

Cardinal offers three bearing types: standard sleeve bearing, the Harley™ sleeve bearing by Cardinal, and the Harley™ sleeve bearing with TecSonics™ bearing wear monitoring.

Fully Pressure-Tested

All Cardinal pump and motor units are pressure-tested to 50 PSIG to ensure the integrity of the complete unit.

Ground Shafts and Dynamic Balancing

All Cardinal sleeve bearing pumps have the bearing journals and thrust surfaces ground between centers to ensure alignment and surface finish. All pump shaft, impeller, and motor assemblies are dynamically balanced for long-term operation.

Electrical Tests

Motor windings are all tested for 60 seconds at (2 x voltage + 1000) to ensure electrical integrity and continuity, with winding resistance taken both before and after the pump is built. All Cardinal pumps are meggar tested to ensure the integrity of the insulation.

Thermo-Siphon Flow

Impellers are designed to permit thermo-siphon flow when the pump is not operating, allowing natural convection even when the pump is completely shut off.

Operating Temperatures

Continuous duty operating temperature ranges from –40ºC (–40ºF) to 100ºC (212ºF).

Rust-Proofing

Special coating is applied to the outside of the pump to protect it from rust. Internal surfaces of the casing can be coated at the customer’s request.

High-Efficiency Motors

Highly efficient oil-immersed motors are available in single or dual voltage, single or three phase, 50 or 60 hertz frequencies.

Rail Service

Cardinal Pumps can also be specially designed to meet existing pump dimensions and performance requirements, including pumps suitable for rail car service.