- Locomotive

-

Freight Car

- Freight Services

- Digital Intelligence

-

Transit

RAIL COMPONENTS

Overview Braking Systems Couplers & Draft Gears Door & Access Solutions Electrical Solutions HVAC & Comfort Systems Power Collection Power & Auxiliary Energy Solutions Sanitation Systems Suspension & Vibration ControlBUS COMPONENTS

Overview Bus Components Doors & Accessibility E-Bus Charging Electric Power Collection Passenger Information & Vehicle SecurityDIGITAL INTELLIGENCE

Radar AIC Event Recorders iSmart Display Passenger Information & Video SecuritySERVICES

Transit Services - Mining

-

Adjacent Solutions

Adjacent Solutions

RAIL INFRASTRUCTURE

Overview Track Products & Materials Signal Wayside Components Vehicle Equipment Electric Power SupplyHEAT TRANSFER & ENERGY SOLUTIONS

Overview Diesel & Gas Engine Cooling Generator, Motor & Transformer Coolers High Temperature Applications

This website no longer supports the Internet Explorer web browser.

Microsoft is retiring and will no longer support Internet Explorer. Please use another web browser to access this website.

Main Menu

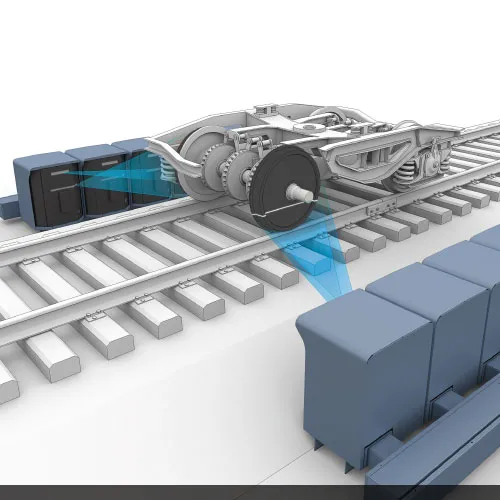

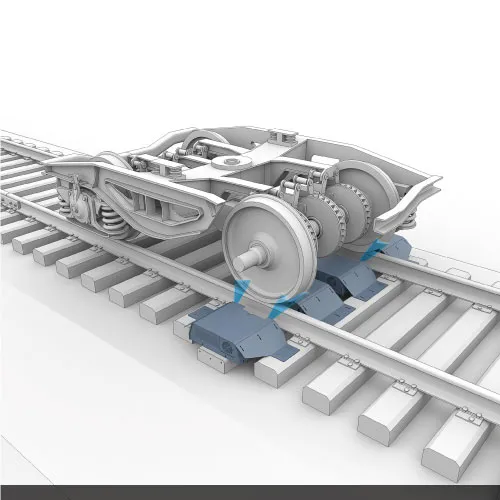

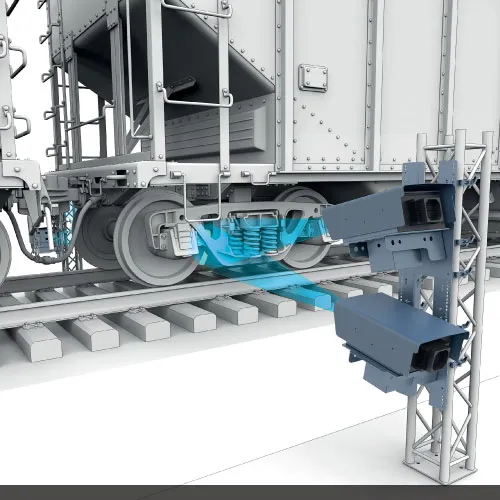

TreadView®

WHEEL SURFACE INSPECTION

TreadView® is an automatic non‑contact optical inspection system that images and inspects wheel surface at mainline operational speeds.

Features

System Features

- Bi-directional system

- Inspection and measurement at mainline operational speeds

- Operates in extreme environments

- Installed off track (concrete or steel base) with no track interference

- Easy maintenance

- Automatic defect reporting

Software Features

- Digital image acquisition/processing

- AEI (RFID) integration

- Automatic reporting

- Web-based database/visualization (with Trimble CMMS™ (Condition Monitoring Management System) or TrainWatch™ software)

- Remote monitoring/control

Specifications

| Function | Wheel surface inspection |

| Application |

|

| Installation Location |

|

| Operating Speed | Inspection and measurement at mainline operational speeds |

| Inspections & Measurements |

|

| Operating Temperature |

Operates in extreme environments |

| Power Requirements |

|

| Periodic Maintenance |

|

| Installation Position |

|

| Remote Diagnostics | Yes |

| Automatic Health Reporting |

Yes |

| AEI/RFID Integration | Yes |

| Air Purge Unit | Yes |