Public-Private Partnerships Key to Driving Adoption of Sustainable Energy Technologies and Alternative Fuels

The world is looking for ways to reduce greenhouse gas emissions, and the transportation industry presents a tremendous opportunity to deliver sustainable solutions. The global rail network is a key part of the answer. The railroads are the cleanest, most efficient means of transporting people and goods on land. Moving freight by rail instead of trucks lowers greenhouse gas (GHG) emissions on average by 75%.

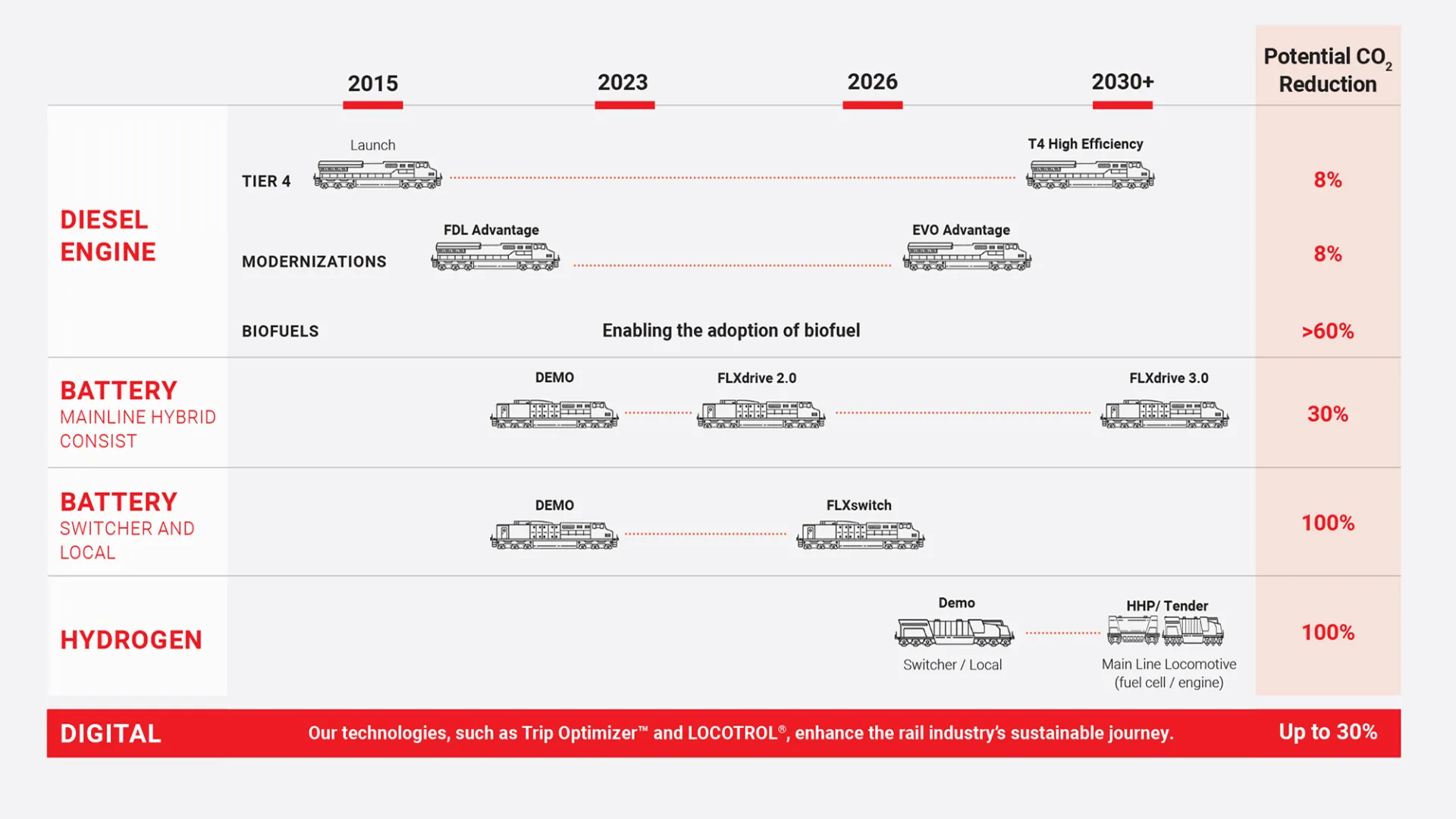

While already in a leadership position on sustainability, the rail industry and Wabtec are focused on continuous improvement, with a goal of a zero-emission rail network. Wabtec’s Evolution Series Tier 4 was the first freight locomotive to meet the U.S. Environmental Protection Agency’s (EPA) stringent Tier 4 emission standards. Nearly 10 years after delivering the first Tier 4 locomotive, the rail industry is on the cusp of technological advancements for powering locomotive fleets with alternative energy sources such as batteries, and eventually, hydrogen fuel cells.

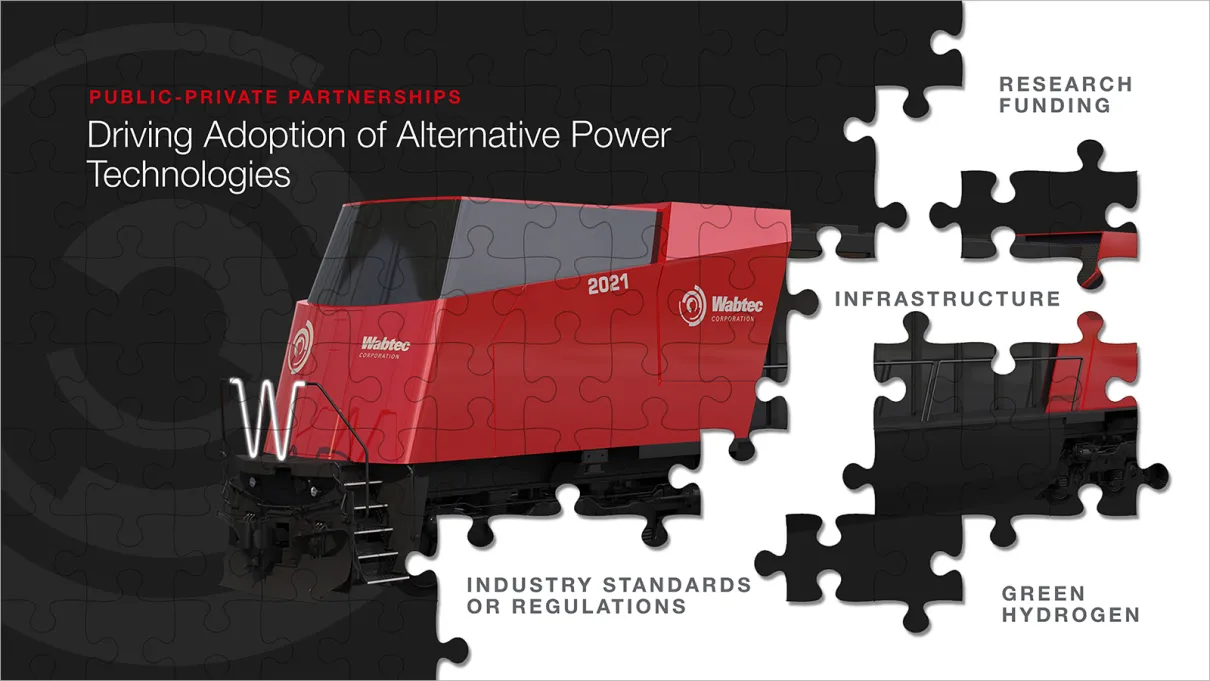

Wabtec is investing and developing alternative energy technologies needed to decarbonize the rail industry. Solving the decarbonization puzzle is more than just introducing breakthrough technologies. Truly decarbonizing the rail industry requires several puzzle pieces falling into place. The industry needs the technology demonstrated to work in the real world, followed by supporting infrastructure, and eventually, commercial adoption and regulatory approvals to name a few.

Progress cannot be accomplished if stakeholders act alone. That is why Wabtec is collaborating with a diverse group of partners – customers, suppliers, academic institutions, national laboratories, and government agencies – to advance alternative energy technologies for the rail industry. Investment in public-private partnerships that bring together these diverse stakeholders could be transformative for the rail industry, as it seeks to decarbonize and develop clean energy infrastructure to help keep its customers moving.

For all the puzzle pieces to come together, the technology, the infrastructure, and the regulatory environment must progress on parallel paths. In Wabtec’s unique position as a leading innovator in the rail industry, the company is partnering with key stakeholders to drive the innovation of alternative fuels, support infrastructure development, while also working with the regulatory bodies to handle these emerging technologies.

Wabtec partnering to advance energy efficiency and alternative fuels

The way to decarbonizing transportation has many paths. Wabtec is contributing to a more sustainable world through a growing number of initiatives. Some are having an immediate impact and others have longer horizons. All of them involve Wabtec working in partnership with its suppliers, customers, outside experts, academia, government, and other participants in the transportation value chain.

Transitioning to biofuels significantly reduces carbon emissions through using more biodiesel (B20) and renewable diesel (R55) in Wabtec locomotives. Wabtec is partnering with BNSF Railway, Union Pacific Railroad and other Class 1 railroads to test these low-carbon fuels that can immediately reduce carbon emissions today. The variety of tests and fuels will allow the company to approve the use of up to 20% biodiesel and up to 100% renewable diesel on the four major Wabtec locomotive engine types.

Wabtec’s new FLXdrive battery locomotive is itself the product of a pioneering public/private partnership. With a $22.6 million grant from the California Air Resource Board, Wabtec, BNSF and the San Joaquin Valley Air Pollution Control District worked together on a pilot of the world’s first 100% battery-powered, heavy-haul freight locomotive, powered by 18,000 lithium-ion battery cells. The success of that pilot accelerated the commercialization of the FLXdrive, with orders from customers in Australia, Brazil, Canada, and the United States.

Decarbonization isn’t just limited to Wabtec’s freight locomotives. The company partnered with Deutsche Bahn to test the rail industry’s first air conditioning system that uses a clean and environmentally friendly natural R290 refrigerant. They are further developing the Green Air System with smart operations that shuts down the HVAC when railcar doors open to save cost and reduce carbon emissions.

Playing a part in hydrogen fuel infrastructure development

Peering further into the future, powering locomotives with hydrogen fuel is one of the more promising alternative energy options for the decarbonization of rail. Wabtec is exploring two approaches. The first involves converting internal combustion engines to work on a blend of hydrogen and diesel. The second is powering locomotives with hydrogen fuel cells.

The work Wabtec is doing with its partners puts them on track to demonstrate proof of concept for hydrogen fueled switching locomotives later this decade. Main line locomotives will follow quickly thereafter.

Locomotive technology roadmap for sustainability

Hydrogen is a clean-burning energy option with enormous potential, but the transition is a complex endeavor that is beyond the capabilities of any single company. Wabtec’s hydrogen public-private partnerships include collaborative research and development agreements with Oak Ridge, Argonne, and Sandia National Labs, three multidisciplinary science and engineering research centers that are centers of excellence in energy-related solutions.

Wabtec is also working with the Department of Energy Office of Science to install a single-cylinder dual-fuel locomotive engine in the National Transportation Research Center on the Oak Ridge National Lab campus. This collaboration presents exciting possibilities for the rail industry. There is a large installed base of more than 20,000 locomotives, which could be retrofitted to burn hydrogen. This option would enable railroads to maximize the investment in their current fleets, while converting the locomotives to a clean-burning energy source.

The Argonne National Laboratory work is focusing on modeling hydrogen injection and combustion. The four-year project will use the lab’s high-performance computers in collaboration with software developer Convergent Science, Inc., to develop simulation software. The team will be able to test and predict combustion engine behavior under changing operating conditions and hardware modifications, speeding the development process at a lower cost to optimize engine efficiency.

The Sandia National Laboratory work, funded by a federal grant, will develop proposed hydrogen standards and regulations for the rail industry. The Federal Railroad Administration and the Association of American Railroads’ Alternative Fuel Tender Technical Advisory Group also participated in Sandia National Lab research on safety and design requirements for hydrogen fuel locomotives.

Wabtec is also at work on locomotives powered by hydrogen fuel cells. The ultimate goal of this effort is a zero-emissions locomotive to replace the diesel-electric locomotives of today. Hydrogen fuel cells do not yet have the power density to power a road locomotive. Wabtec is working with various suppliers to develop fuel cell solutions for locomotive applications.

What infrastructure is needed for hydrogen power?

Hydrogen-powered locomotives are just a part of what it will take to make this alternative fuel commercially viable. It will require a complete infrastructure overhaul.

The primary barriers to a hydrogen-powered rail industry today include:

- The high cost of green hydrogen in comparison to diesel fuel

- Lack of storage and refueling facilities that provide access to the fuel along rail routes

- Railroad operational changes around safety procedures, crew and craft training, labor union agreements, maintenance, coordination with first responders in the case of incidents and accidents, and more

To jumpstart the hydrogen economy, the Infrastructure Investment and Jobs Act (IIJA), signed by President Biden in 2021, set aside $8B in federal funding for the development of the Regional Hydrogen Hub program at the Department of Energy. This program aims to build out key components of the hydrogen infrastructure at seven regional hydrogen production hubs. These hubs are targeted to produce up to one third of the hydrogen needed in the market.

Wabtec supported the Department of Energy Hydrogen Program, contributing to the development of their hydrogen hub implementation strategy. Wabtec also supported a few applications to secure a share of government hydrogen hub funding. They worked with HyVelocity, a collaboration by non-profit research organizations and academia on the Gulf Coast. They similarly supported the Machh2 Alliance for the Midwest regional hydrogen hub.

Wabtec is partnering with its customers to ensure that the needs of the rail industry are well understood, as this new infrastructure is developed at regional hydrogen hubs. Using hydrogen to power locomotives today would be a challenge without significant technology advances and infrastructure.

Fueling a locomotive would be time consuming. It currently takes under 30 minutes to fill a 5,000-gallon diesel tank. Refueling an equivalent amount of gaseous hydrogen would take 6.5 hours, disrupting logistics, and negatively affecting asset utilization.

Yet even before the refueling issue can be addressed, locomotive operators need infrastructure that provides access to low carbon hydrogen. Most hydrogen is produced via electrolysis, which requires affordable and abundant water and electricity. Rarely are these hydrogen production resources located near railyards, creating a transportation and storage challenge.

With the appropriate safety features and regulatory support, rail could be the “virtual pipelines” for the hydrogen economy of the future. Rail could easily connect to hydrogen production facilities with distribution networks that will fuel locomotives and other modes of transportation. Transporting hydrogen by rail is more cost efficient, faster to implement, and offers greater flexibility over pipelines. than using trucks. Rail transport brings the fuel closer to users via existing infrastructure. Rail cars used to transport hydrogen can also function as on-site storage tanks to further reduce infrastructure build-out costs. The infrastructure will also need equipment that meets railway standards for larger scale, heavy-duty applications.

Ultimately, railroads running Wabtec hydrogen-fueled locomotives will also be among the users of this alternative fuel, closing the loop of the hydrogen value chain.

Working through regulatory obstacles

New technologies sometimes face complex and unforeseen regulatory issues that require partnership and cooperation between regulators and industry. “As a global rail technology leader, it is important that Wabtec weigh in with its strong expertise and experience as the regulatory community seeks to develop new regulations and standards that will apply to the hydrogen economy,” says Jennifer Shea, Wabtec’s corporate vice president for regulatory. “The company’s research and development efforts in participation with national labs and academic institutions, as well as our participation in leading industry coalitions, provide unique opportunities to demonstrate Wabtec’s role in enabling technologies that will lead to the decarbonization of the rail industry.”

Thinking ahead, Wabtec and Sandia National Laboratories documented the Risk Assessment of Design and Refueling for Hydrogen Locomotive and Tender, a project that gives the regulatory community and industry vital information when developing technical standards for the hydrogen economy.

The company is also active in the Fuel Cell & Hydrogen Energy Association in informing federal policies, along with regulations, codes, and standards.

A commitment to partnerships that are driving adoption of alternative fuels

“We are looking forward to seeing the hydrogen infrastructure being built for use in rail,” says Philip Moslener, Wabtec’s corporate vice president for advanced technologies. “It is vital we reduce carbon emissions today. We are supporting customers with clean energy solutions that they can implement now, that also increase the efficiency of their operations and benefit their bottom lines.”

It is easy to get caught up in the hype of various alternative energy options. Because Wabtec products are where the wheel meets the rail, the company’s role is to make these visions a reality. That means understanding the technology and knowing what makes practical sense. Wabtec is making prudent investments in well-managed research and development projects and is working with carefully selected partners in government and industry. The Wabtec philosophy is that success is not measured by ambition, but in what they accomplish for the global rail network.

It is through working together with governments and industry partners that Wabtec will advance developments that make the market ready for decarbonization. As that happens, Wabtec is ready with the products the market needs to roll forward to a greener future.