- Locomotive

-

Freight Car

- Freight Services

- Digital Intelligence

-

Transit

RAIL COMPONENTS

Overview Braking Systems Couplers & Draft Gears Door & Access Solutions Electrical Solutions HVAC & Comfort Systems Power Collection Power & Auxiliary Energy Solutions Sanitation Systems Suspension & Vibration ControlBUS COMPONENTS

Overview Bus Components Doors & Accessibility E-Bus Charging Electric Power Collection Passenger Information & Vehicle SecurityDIGITAL INTELLIGENCE

Radar AIC Event Recorders iSmart Display Passenger Information & Video SecuritySERVICES

Transit Services - Mining

-

Adjacent Solutions

Adjacent Solutions

RAIL INFRASTRUCTURE

Overview Track Products & Materials Signal Wayside Components Vehicle Equipment Electric Power SupplyHEAT TRANSFER & ENERGY SOLUTIONS

Overview Diesel & Gas Engine Cooling Generator, Motor & Transformer Coolers High Temperature Applications

This website no longer supports the Internet Explorer web browser.

Microsoft is retiring and will no longer support Internet Explorer. Please use another web browser to access this website.

Main Menu

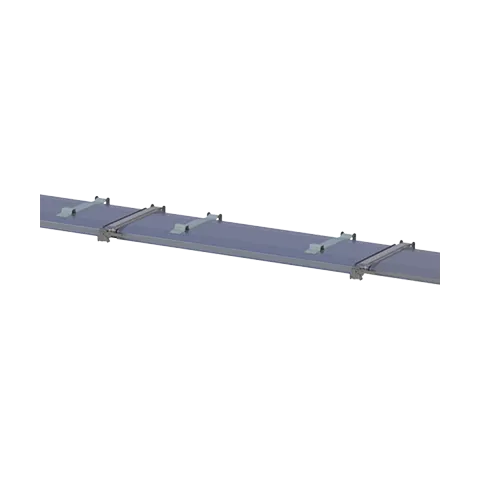

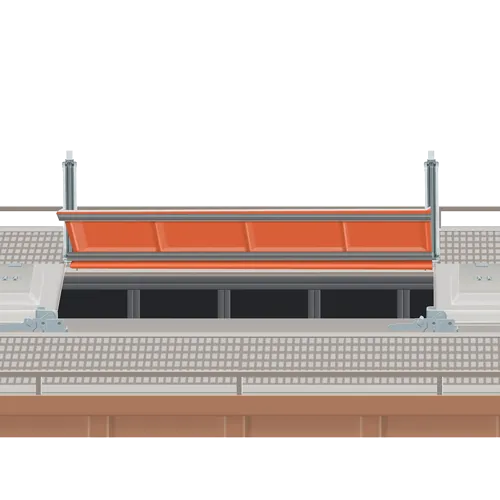

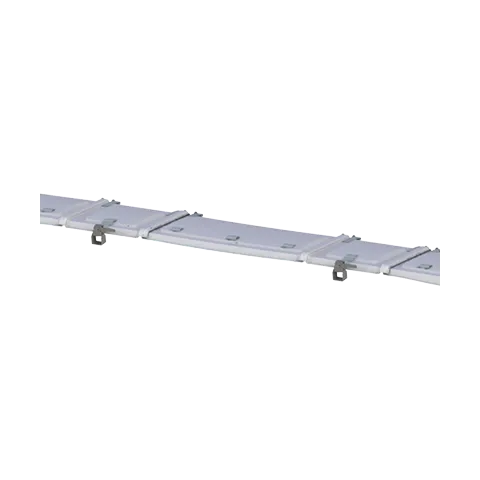

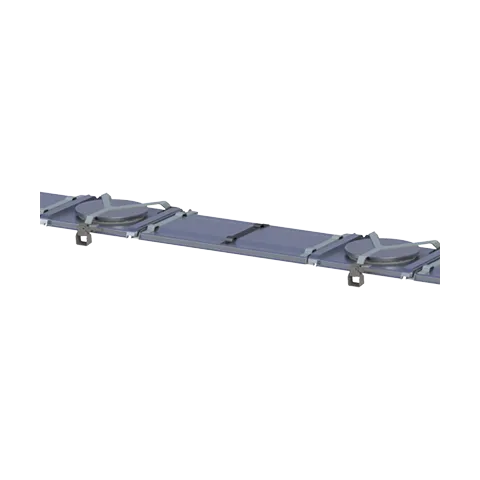

Conventional Covers

HATCH COVER SYSTEMS

The traditional covering system since the late 1960’s typically utilizes four to six rectangular shaped trough covers, with three to five batten bars. These covers generally range from 7 to 13 foot in length and the outer most covers on the car have either square or round ends depending on the trough style.

Our conventional covers are offered in fiberglass and aluminum, utilizing stainless steel batten bars, and a hollow chamber trough gasket design. Along with material options, conventional covers are offered in multiple sizes with numerous hinge positions and locations. This flexibility creates a multitude of cover combinations available to suit your exact requirements.

Common Commodities:

- Grain

- Soy Bean Meal

- Malt/Barley

- Salt

- Potash

- Corn Gluten Meal

- Lime

- Fertilizer

- Soda Ash

- Bentonite/Clay

- Dried Distillers Grain (DDG)

Call us for further details

- 1-800-821-2376 (US & Canada)

- +1-816-257-5450 (International)

Conventional Cover Systems

Features, Options & Specifications

- Features

- Additional Options

- Technical Specifications

- Operating Instructions

Features

Gasket System

The hollow chamber trough gasket design typically provides up to 3/4 of an inch compression between the cover and coaming of the car. The internal gasket of the batten bar overlaps the end flanges of two adjacent covers, providing a good weather resistant seal.

Fiberglass Conventional Covers:

- 4 Layer Fiberglass Laminate (Typically 5/32”)

- Durable Grey Gel Coat Finish

- Depth of Pan and Molded in Ribs add Superior Cover Strength

- Crown Shape Sheds Water

- Light Durable Cover

- AAR Approved Designs

Aluminum Conventional Covers:

- 5052_H34 Aluminum (0.125”)

- Strong 6061_T4 Extruded End Channels

- Bare Aluminum Finish

- Fully Welded Construction

- AAR Approved Designs

Additional Options

- Multiple Trough Widths Available

- 20” & 24” = Fiberglass

- 20”, 24”, & 30” = Aluminum

- Numerous Cover Lengths Available

- Numerous Hinge Positions Available

- Gasket Options

- Food Grade Gasket

- Standard Black Gasket

- Various Bumper Options to Suit Different Car Designs

- Galvanized Coated Bumpers

- Various Size and Locations

- Multiple Hardware Configurations

- Galvanized Steel Hardware

- Stainless Steel Hardware

Technical Specifications

| FIBERGLASS CONVENTIONAL COVERS | |

| Material | 4 Layer Fiberglass Laminate |

| Material Thickness | 5/32” (0.156”) |

| General 13" Overall Cover Weight | 84 lbs. |

| ALUMINUM CONVENTIONAL COVERS | |

| Material | 5052_H34 Aluminum |

| Material Thickness | 1/8” (0.125”) |

| General 13" Overall Cover Weight | 103 lbs. |

Operating Instructions

With a conventional cover system, any one cover can be opened at anytime if the corresponding locks and batten bars are unlocked. There is no sequence required when opening this cover design, but it is suggested they be closed in sequence. For safety reasons we do not recommend walking inside an open cover, so closing in sequence can prevent this from occurring.

Opening:

- Open the two locks associated with the corresponding cover to be opened.

- Once locks are opened, the batten bars can be swung out of the way.

- The desired trough cover can be opened.

Closing:

- Wabtec recommends that the covers are closed in a sequential order to prevent walking inside the covers.

- While walking on the running boards, continue down the length of the car closing the covers and/or batten bars.

- Walk across the running boards to the lock side of the car. Walk the length of the car, locking each lock to secure the batten bars and covers in place.