Wabtec innovation addresses a decades-long blind spot in freight rail: Visibility into railcar location, status, and condition.

A hole in the bucket

Freight rail holds a number of well-documented advantages over trucking and other modes of transport, including superior:

- Efficiency – Rail consumes about 4x less fuel than trucks.

- Cost-effectiveness – Rail has a significantly lower cost-per-ton-mile than truck.

- Environmental Health and Safety – Rail emits about 75% fewer GHG emissions than trucking and is up to 28x safer on a ton-mile basis.1

An oft-cited figure from the Association of American Railroads puts this all in perspective, estimating that an additional 83 million trucks would be needed on U.S. roads if railroads did not move freight.

And no one wants that.

Yet, in a 2020 Oliver Wyman survey of large rail shippers, 100% of executive respondents found trucking superior to rail on all attributes related to “customer experience,” including on-time performance/reliability, proactive problem resolution and accountability, and shipment visibility.

Freight rail operators, as well as their customers, know their mode’s many strengths. But the time is now to address the weaknesses. Shipment visibility, which impacts many dimensions of the customer experience, tops the list.

Sure, it may have been funny for two young partiers to ask, “Dude, where’s my car?,” but not being able to provide that information – and more – quickly, confidently, and with precision to today’s demanding freight rail customers is no laughing matter.

Vying for visibility

One reason freight rail holds so many measurable advantages over competing logistics modes is the strong innovation engine behind it, one powered by Wabtec for more than 150 years. Ongoing advances in engine efficiency, renewable fuel use, remanufacturing, braking, and controls, electrification, and other areas pioneered and honed by Wabtec continue to translate into measurable gains for its customers and the industry at large.

But visibility had proven a different beast.

“I think a lot of people outside the freight rail industry would be shocked that the on-demand, real-time visibility afforded by companies such as Amazon and Uber – capabilities that many consumers now take for granted – aren’t broadly available in freight rail,” says Aage Lindstad, Network Solutions Architect, at Wabtec. “But industry insiders are well aware of the hurdles that have kept railcar owners and end customers in the dark as to car location and shipment arrival times.”

That’s not to say GPS and other forms of telemetry are absent from modern freight rail. Many Class I railroads deploy Wabtec’s Expert on Alert system, which uses GPS-enabled sensors to transmit locomotive data to Wabtec’s Global Performance Optimization Center for remote monitoring of locomotive health.

But, delivering a locomotive-centric capability is different than providing telematics for every car in a freight rail network.

“The real barrier to bringing real-time visibility to our industry has been two-fold,” offers Andrew Parker, Director, Product Management for Railcar Telematics at Wabtec. “First, the price point of sensors and other wireless communications hardware was never conducive to solving the problem at scale. And, second, these same devices were never durable enough to match the demanding environmental conditions of railcars and their service requirements.

“For example, no freight fleet operator can realistically swap out batteries on thousands of sensors every few months – remember, most railcars have no power – so getting the right devices to the right level of maturity, at the right price point, is a critical gating factor for achieving a scalable solution.”

Visibility as a performance enabler

Fortunately, that moment has come.

First, by focusing intently on the problem and keeping its finger on the pulse of advances in the field, Wabtec’s Telematics team found a hardware innovator capable of turning the tables on device cost and durability.

Next, and in true Wabtec fashion, the team didn’t settle on solving just one problem – it sensed a ‘twofer.’ As a result, Wabtec is not only offering freight rail customers the ability to answer the question, “Where is my railcar?,” but also, “What condition is it in, as well as its contents?”

Wabtec’s Railcar Telematics solution provides end-to-end visibility, health, and condition status built on the bedrock of affordable, ruggedized sensors optimized for the realities of the railcar:

- Battery-life measured in years not months;

- An ability to withstand temperature extremes;

- High reliability; and

- An affordable price.

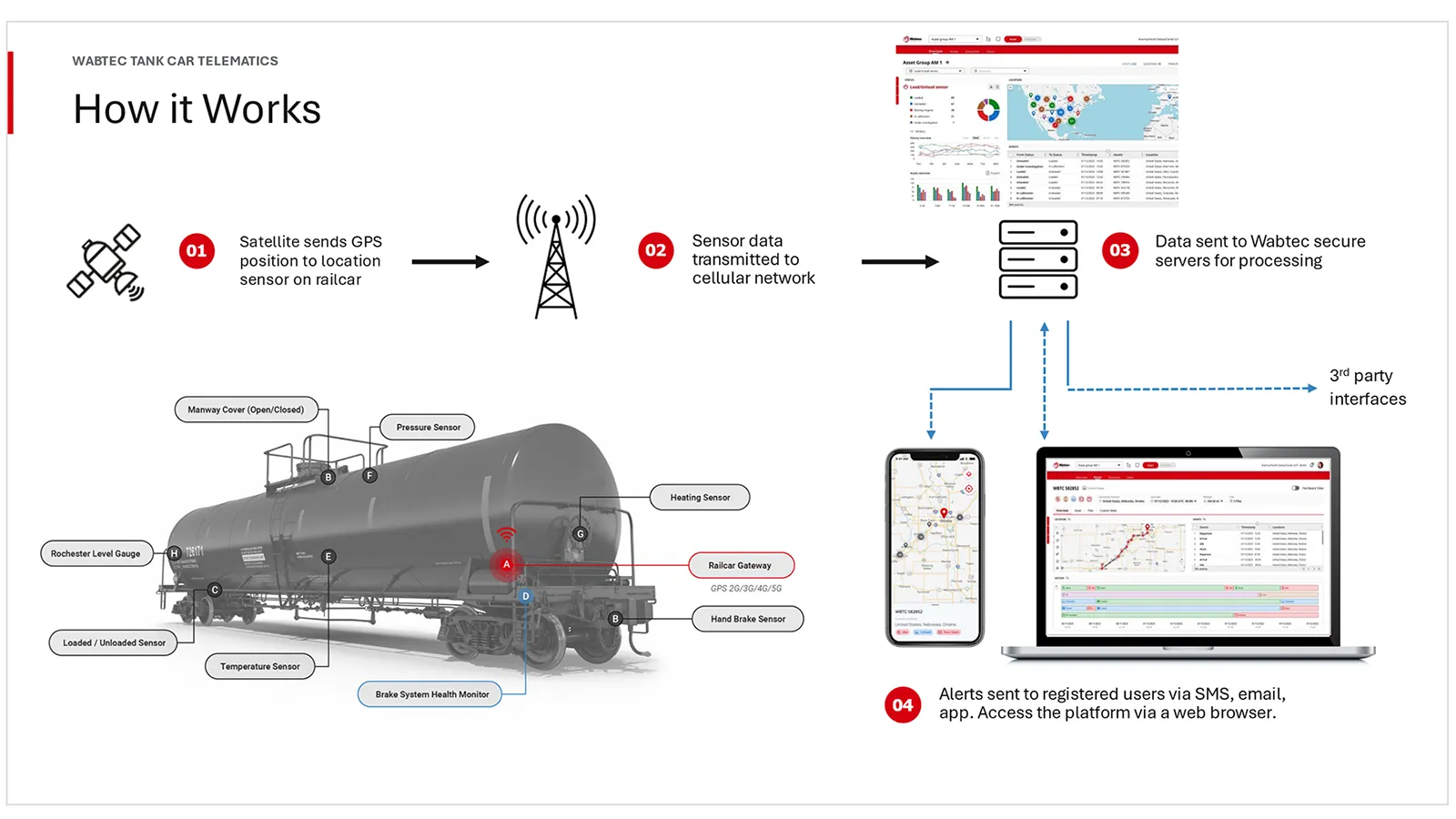

Combining sensors, gateways, wireless communications, and analytics, the offering includes a comprehensive suite of solutions that tracks real-time location and monitors key attributes such as handbrakes, hatches, doors, and loaded/unloaded status of a railcar, as well as cargo temperature and pressure for tank containers.

That “and” is important. Yes, customers want to know where their railcar is, but in service of something even more valuable: performance. They want to know when it is arriving and the condition of the goods it is carrying. That’s exactly what the additional capabilities of the Wabtec Railcar Telematics solution support, including the use of health data to improve railcar maintenance, reliability, and safety.

For example, railcars outfitted with telematics at scale will produce new real-time, well-documented data sets for delivering next-gen ETAs. Loading and unloading sensors will provide real-time railcar status to unlock greater utilization. And when customers ask for greater productivity, telematics can respond with precise location information that enables greater yard optimization and automation.

All aboard!

“This new technology, in association with the launch of Rail Pulse’s new data platform to share location, condition, and health data in real time with car owners, railroads, and customers, provides the spark needed for a renaissance in the freight rail industry,” concludes Lindstad. “The opportunity to turn the North American fleet’s 1.65 million railcars into smart, connected assets by using this technology is a game changer, one capable of tilting the customer-experience balance back in favor of rail and, with it, driving a major modal shift.”

And the stakes couldn’t be higher. Every ton of freight shipped by rail leads to fewer highway fatalities, less congestion and pollution, decreased fuel consumption, and reduced infrastructure cost. A modal shift, one that can drive safer, cleaner, more efficient shipping, and with it billions of dollars in economic opportunity, is within reach. The freight rail industry just needs to grab it.

It’s time to know where your railcar is – and how it’s doing. Now you can.

Sources: Association of American Railroads Data; Oliver Wyman