November 2024

Back on Track

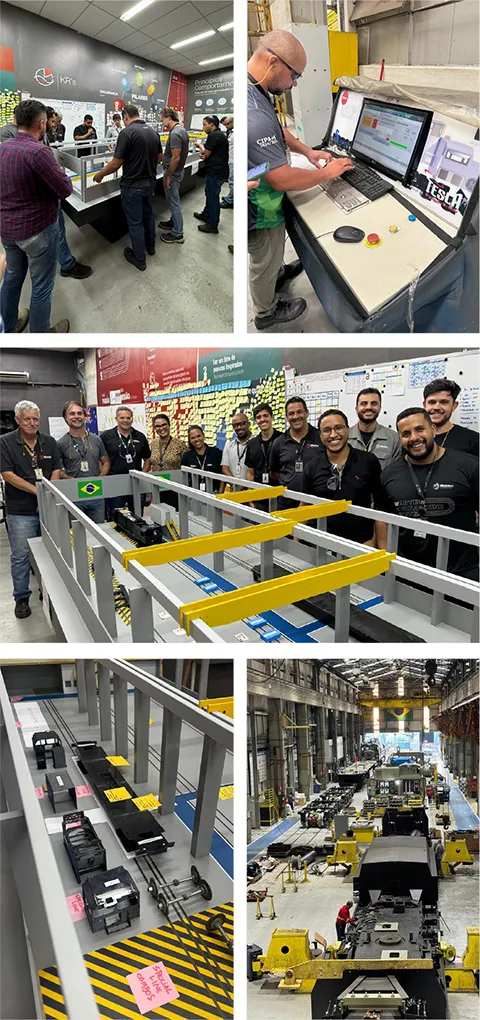

Success in the face of adversity

Bruno Cury discusses the ways our Contagem facility intends to improve in 2025.

Our Contagem facility experienced an abnormally tough 2024. A perfect storm of external events, changes in senior leadership, and a large new product introduction led to a difficult year. Here, Bruno Cury, Operations Director, discusses these issues and the ways their team is working to get the Contagem site back on track.

Q: What challenges did the facility face this year?

Bruno: “This year, we faced new challenges and suffered from difficulties that carried over from the previous year. There were large fluctuations in the supply of imported items due to external events, changes in senior leadership, large NPIs (the largest since 2015), and the break of more than two years without reportable accidents — with four accidents in the first half of the year. These challenges are connected to the complexity of our multi-solution plant combined with a 25% increase in volume in new locomotives from 2023 to 2024.”

Q: What are some thing you’re proud of with your team this year?

Bruno: “Regardless of our obstacles, this team has proven to be a team that stays united and connected in crisis situations. We are a resilient team that demonstrates the ability to overcome adversity and daily problems. In addition, it was a year in which we created connections with Wabtec teams outside our plant, which was essential for deliveries and for solving problems we knew were coming. I also proudly recognize the strengthening of the team – bringing in more seniority and preparing us even more to deliver on our commitments, and ensuring quality and safety.

“To have a smoother 2025, we’re spending time analyzing the obstacles, making sure we understand the lessons learned, investing in the team’s training and experience, and working as a team to support each other.”

Q: How are we preparing for a stronger 2025?

Bruno: “We have divided our team into project-focused groups related to our volume readiness. These teams will be addressing topics like line side support, manufacturing instructions, materials management and presentation, capacity preparations and simulations, and sponsorship to increase our headcount by 30%. We are focused on solutions for the factory floor, developing leadership through conflict management and real-time problem solving, and working on accountability and ownership.”