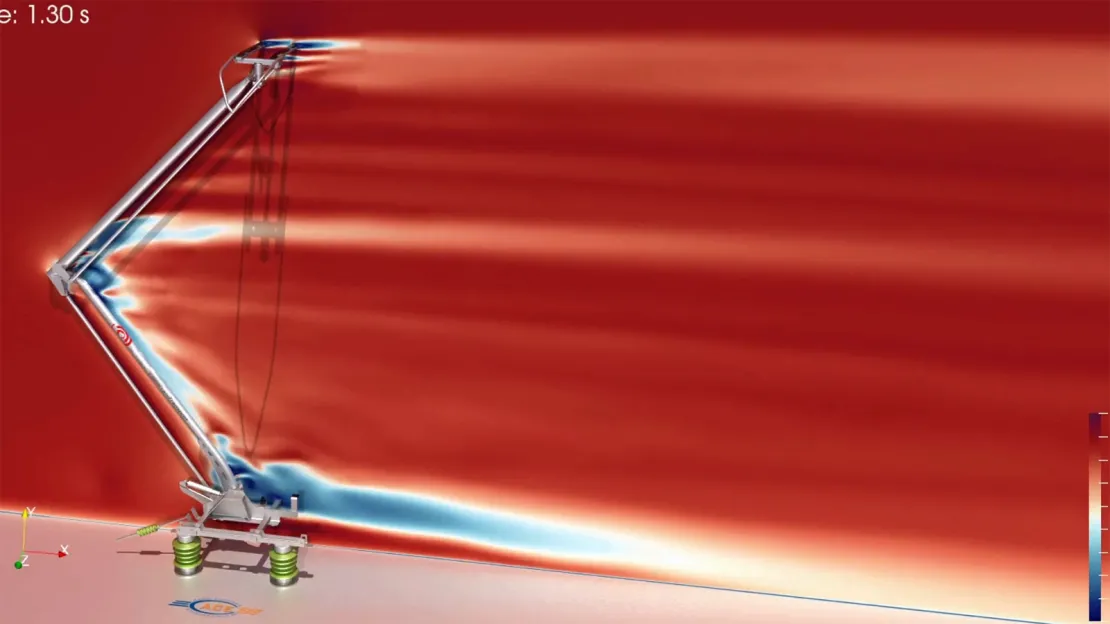

Wabtec uses computational fluid dynamics to optimize design and performance under a variety of conditions.

Over 100 Years into Its Evolution, the Panto Still Surprises as a Hot Spot of Innovation

Don’t try this at home

If someone were ever foolish enough to stick their arm out the window of a bullet train barreling down the tracks at top speed, they would likely get a taste for the forces at play on another kind of arm, the one perched atop the train. Meet one of transit rail’s most miraculous yet unsung components – the pantograph.

And the aerodynamics are just one challenge this versatile piece of equipment faces as it performs its quintessential function, pulling charge from a catenary wire – that long electric line above the tracks – and directing it appropriately to power the train.

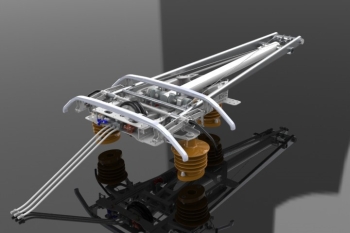

Combining the precision and agility of a ballerina with the brute force of a charging rhino, the panto is one of the most durable, dynamic, and essential pieces of modern rail equipment. Coming in almost limitless varieties, the pantograph continues to inspire the collective imagination of the rail industry’s top engineers to make it lighter, stronger, more conductive, and even more responsive than ever before.

The ‘single arm’ century

While the invention of the “diamond shaped” pantograph traces back to John Q. Smith and commuter train travel in the San Francisco Bay of 1903, the perfection of the panto is widely attributed to Wabtec forebear Louis Faiveley. Not only did he improve upon the diamond style panto with his own enhanced design in the early 1920s, he eventually broke the mold entirely with the invention of the single-arm panto. Faiveley’s step-change design went on to set the world speed record (331 kmh/206 mph) for an electric powered train that same year, 1955, and is the industry standard to this day.

And with ongoing innovation to the single arm panto, record breaking performances followed. New Wabtec panto models enabled trains to top speeds of 515 kmh/320 mph and 574 kmh/356 mph in 1990 and 2007, respectively. Beyond setting new speed records, Wabtec pantographs achieved many firsts throughout the 20th and 21st century, spanning innovations in material design, footprint size, rooftop integration, arm reach, and power modes, contributing to a panto proliferation that exceeds 150 types and more than 90,000 installed worldwide.

The Need for Speed

But let’s get back to speed. The diamond-shaped pantos of the early 20th century matched the rigidity and voltages of that era’s overhead wires. Yet their bulky shape wasn’t conducive to high speed, and the increased voltage on the catenary wires. Faiveley seized the opportunity to develop a new and better kind of pantograph – one that was lighter, more aerodynamic and conductive, and possessing more dexterity to keep the panhead in constant contact with the wire.

Ironically, Wabtec’s pantograph designers and engineers are still grappling with these same challenges today in pursuit of the optimal panto.

“Pantograph development principally comes down to achieving stable dynamic performance; ensuring high quality current collection; and delivering both in the packaging or gauging that the customer requires,” says Matt Atkins, Power Collection Engineering Director at Wabtec. “By dynamic performance, I mean the panto has to work in real world conditions (think weather, wind, speed, the bounce of the train and movement of the wire for starters); and for current collection consider these same factors again plus a laundry list of electrical capacity and mechanical engineering concerns. Ultimately, we need both to power a train effectively, but there are a host of constraints doing everything possible to get in the way, and which it is our job to outflank and overcome.”

Another way to understand the pantograph design and engineering challenge is to consider a short list of a pantos “must haves”:

- It must be light.

- It must be strong.

- It must be aerodynamic.

- It must work in two directions (forward and reverse, unlike an airplane!)

- It must conduct electricity.

- It must manage friction.

- It must work in an everchanging, dynamic environment.

- And it must be configurable to a world of varying voltages, overhead wire heights, and train types, as well as to whatever comes next (see below).

This list, of course, never ends. And no one knows this better than the Wabtec panto team or is more dedicated to refining and improving the company’s pantograph portfolio across these often competing demands.

The Dream of the Perfect Pantograph

Wabtec’s pantograph engineers around the world share an obsession: developing the perfect panto. So what might that look like? Again, Matt Atkins has some ideas.

“I think we can all agree that the perfect panto will be super-lightweight, and that’s going to require innovation in the panhead, which is inherently metalized carbon. Today, the denser the panhead material, the more current capacity it can handle. But that adds weight, which is the enemy of speed. So the holy grail would be a very light, very high-current-capacity pantograph,” said Atkins.

“And that’s only half the story. We haven’t even mentioned the lengths pantographs literally need to go to meet our customers’ needs. Our customers are always pushing for pantos to have a very large physical range – an ability for the panto arm to dexterously extend varying distances – so they can use their trains on different tracks with different catenary wire heights. A great example of this is in India, where Wabtec is a market leader in high-reach pantos.”

Panto of the Future

Along with engaging the physics, materials, and electrical and mechanical challenges that come with panto innovation, Wabtec must also contend with a more human variable: government regulation.

As it stands today, one of the biggest conversations in the world of pantographs is how best to meet the ERJU mandate of “airless” trains. On paper, the prospect of airless trains look great. By removing large air compressors and piping from locomotives and transit cars, trains will become lighter and more efficient.

But this shift presents a big challenge for pantographs, because many of them require air to operate. All that dynamic, real-time movement that keeps the panhead tight to the catenary is typically enabled by the panto’s air-pressurized cylinders or bellows.

The answer ultimately could lie in an all-electric pantograph, a.k.a., the “ePanto,” which Wabtec has designed and is currently prototyping and readying for validation soon. The challenges are many, including introducing 1) an electric actuator that can move the panto arm as responsively as air-driven systems, and 2) an electric auto-drop system that can shut down a panto at the same sub-second response rates of current systems that enhance train safety. Additionally, there are electrical insulation issues to solve between pantograph component-level operational voltages and collecting voltages in the overhead line.

“ePantos are a potential game changer for Wabtec and the industry at large in that they eliminate the need for a lot of equipment that is expensive for car builders to manufacture and for customers to maintain,” said Philippe Geoffroy, Power Collection Pantograph Product Development Domain Leader at Wabtec. “But they will require significant innovation, a challenge Wabtec has never shied away from.

“In assessing the current frontiers of pantograph innovation, I can’t help but look back at what Faiveley accomplished and the successful course he set for this company. It is amazing to me that more than 100 years after his first big innovation in pantograph design we are still contending with the same physical forces and electro-mechanical realities he did – and that, like him, our diligence and creativity are paying off with tangible advances for our customers, company, and industry.”